The Low friction rolling diaphragm cylinder utilizes rubber manufacturing technology which has been our main business domain since its founding over 100 years ago. The silk hat shaped diaphragm built inside the cylinder rolls as the rod extend smoothly by air pressure. Nowadays, when it comes to low friction air cylinder, nothing is better than the rolling diaphragm cylinder.

Rolling Diaphragm Cylinder

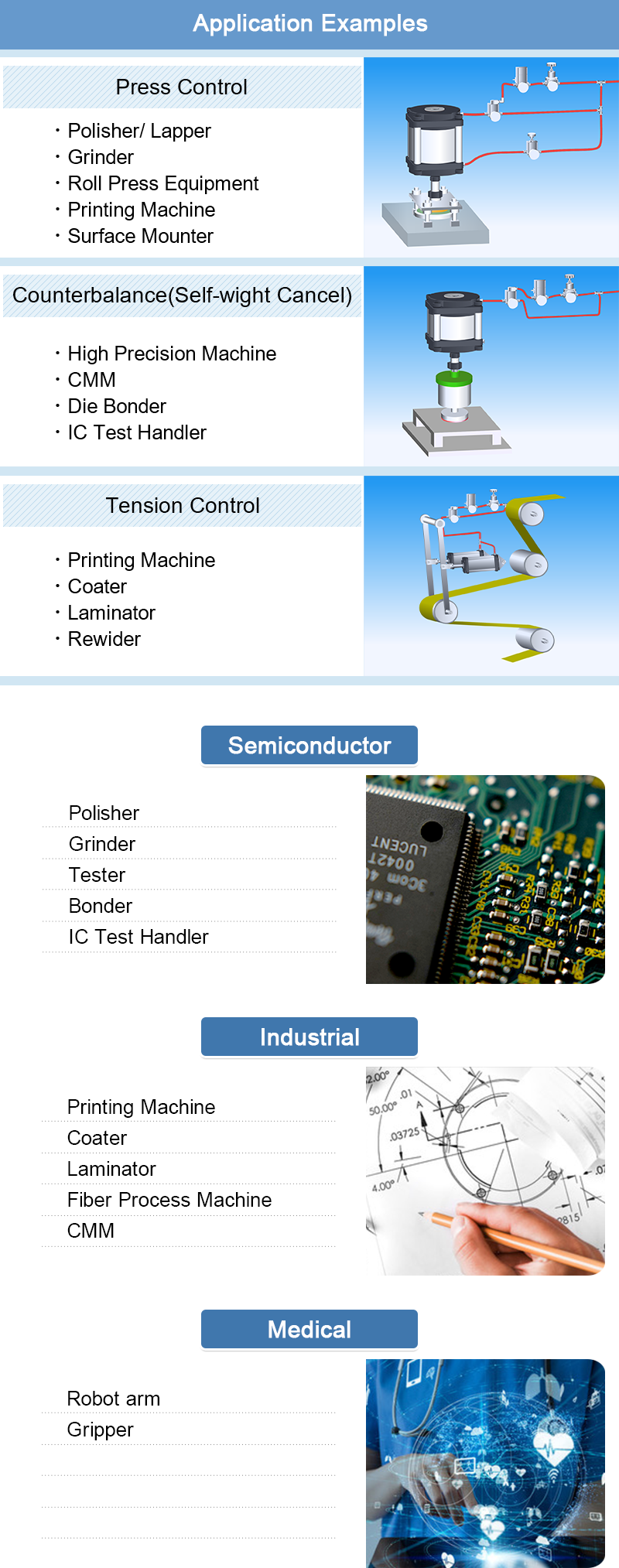

This air cylinder is best suited for pressure control by air. We use it for tension control. Although we use electric actuators for position control, we think this pneumatic type is most convenient for pressure control. Smoothly moving diaphragm cylinders are very easy to use

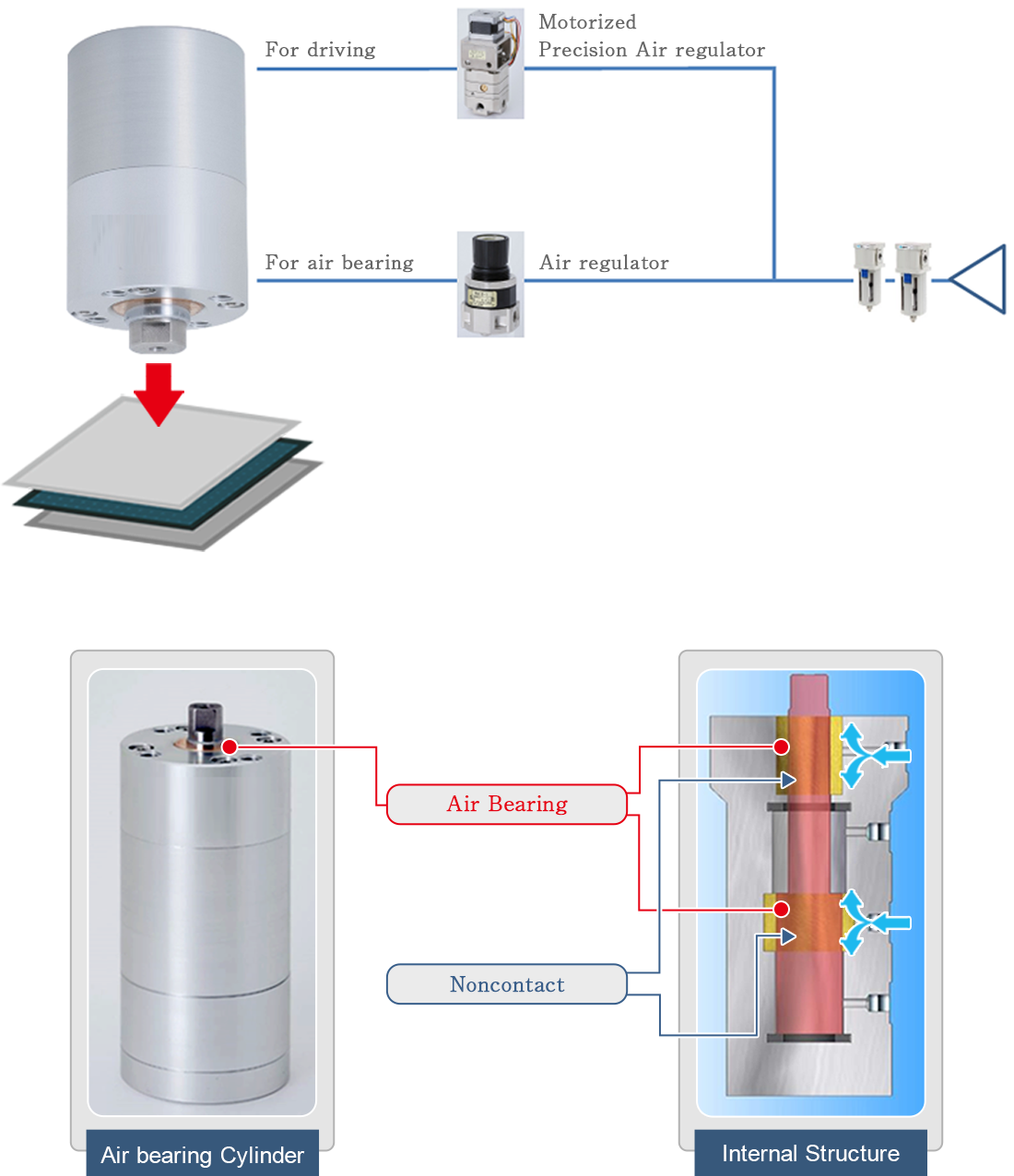

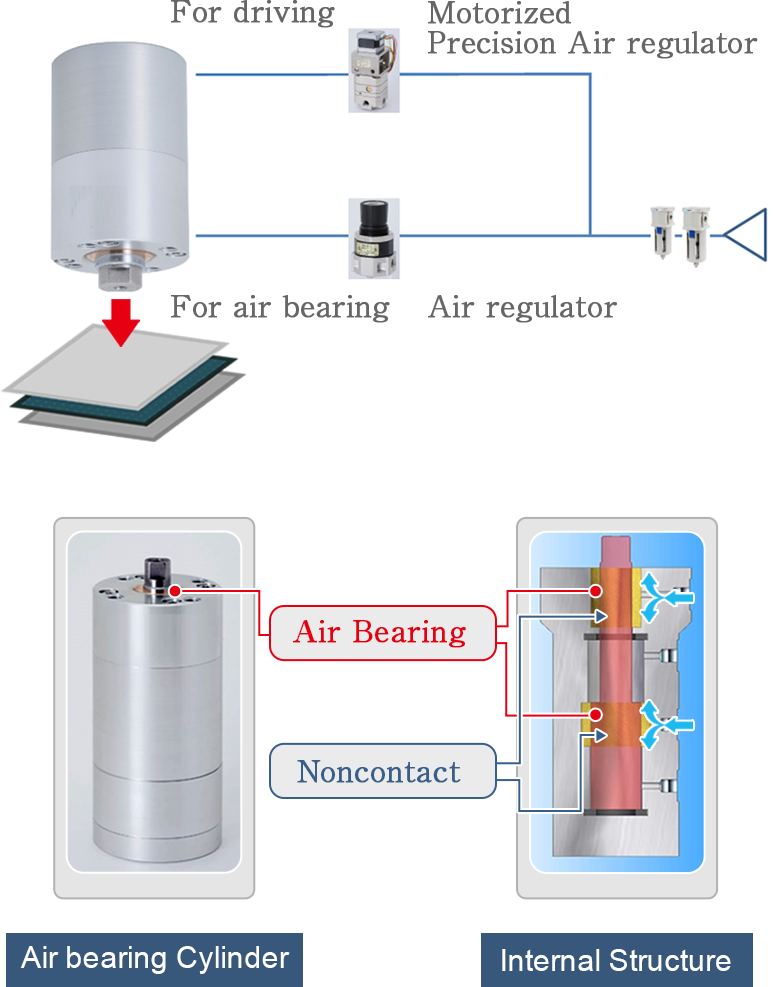

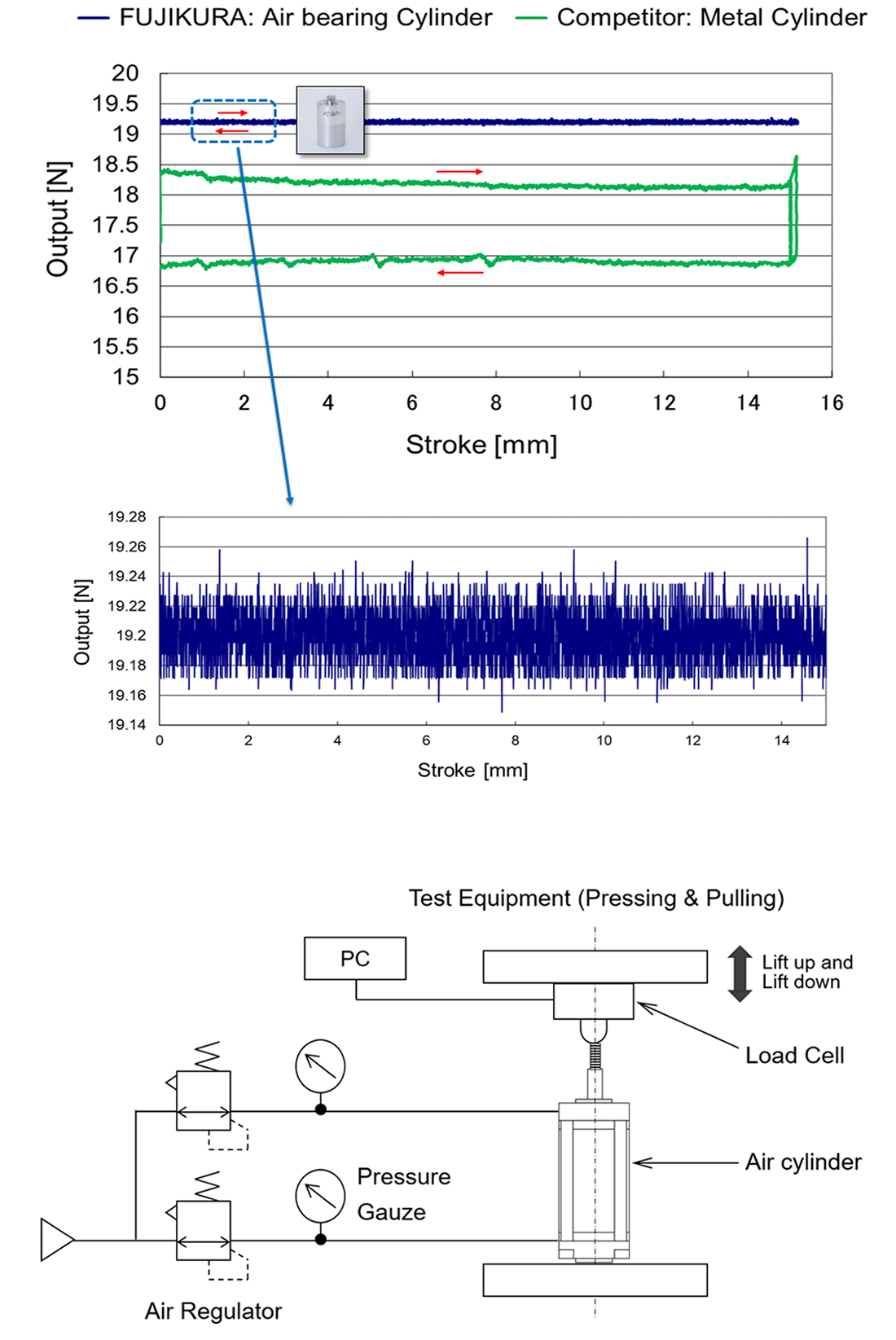

With the development of the semiconductor and nanotechnology markets and the increasing dema nd for ultra-precision parts, machines and equipment used to process them had to evolve as well. This led us to seek the ultimate low friction cylinder and finally we develop and release the air bear ing cylinder that allows the rod to move without any contact as being lifted by an air film.

Air bearing Cylinder

We use this for IC chip bonding machine. Since we want to keep ultra-low pressure at a constant force, we need to use cylinders with very low sliding resistance. Therefore, we use the air bearing cylinder that has no resistance

Semiconductor market is booming due to the development of IOT and smart factories as well as equipment for medical technology that uses nanotechnology to a higher level and the demand for precision machining is increasing too.

Air bearing cylinders realize high precision optimum load control because of zero slide resistance. When they come to with our air regulator “RS-M/S” series, the resolution of Air bearing cylinder “ACS-10-16 Pressure-receiving area 78.5mm2 ” is 0.00785N 0.8g

| Operating Style | Single action (Push) / Double action |

|---|---|

| Cylinder Diameter (mm[in.]) | 10 〜 100 [0.39 〜 3.93] |

| Stroke (mm[in.]) | 20 〜 160 [0.79 〜 6.30] |

| FluidWorking | Clean compressed air (No lubricator required) |

| Working Pressure Range (MPa[psi]) | 0.01〜0.6 (※1)[1.5〜87.0] |

| Working Temperature (℃[゚F]) | 0〜60 [32〜140] |

| Bearing type | Sintered Metal |

※1 The supply pressure to the air bearing should be at least +50kPa[7.25] than working pressure.

※2 Customization Available

| Company name | FUJIKURA COMPOSITES Inc. |

|---|---|

| Establishment | 1901 |

| Capital | JPY3.84 billion (USD36.6 million) |

| Employees | 2,550 (group) *as of end March 2020 |

| Revenue | JPY31,999 million (USD304 million) *2019 |

| Certificates | ISO 9001 (2015) - Quality Management System ISO 14001 (2015) - Environmental Management System ISO 13485 (2016) - Medical Device QMS |

Click here for other precision air cylinder

Rolling diaphragm cylinder, Resin packing cylinder and etc.